MOISTURE/HUMIDITY CONTROL BY CLIMECH INDIA

MOISTURE CONTROL FOR ELECTRODE STORAGE

Welding is an important tool for efficient maintenance of plants and quality fabrication in industry. The welding electrode or rod consists of a metal wire with a baked chemical/mineral coating. The coating of the electrode holds the key to quality welding. Welding defects caused due to poor quality and weak welding are a nuisance because It is unsafe and unreliable Weak welds are dangerous for heavy machinery or large structures It gives a flawed finish

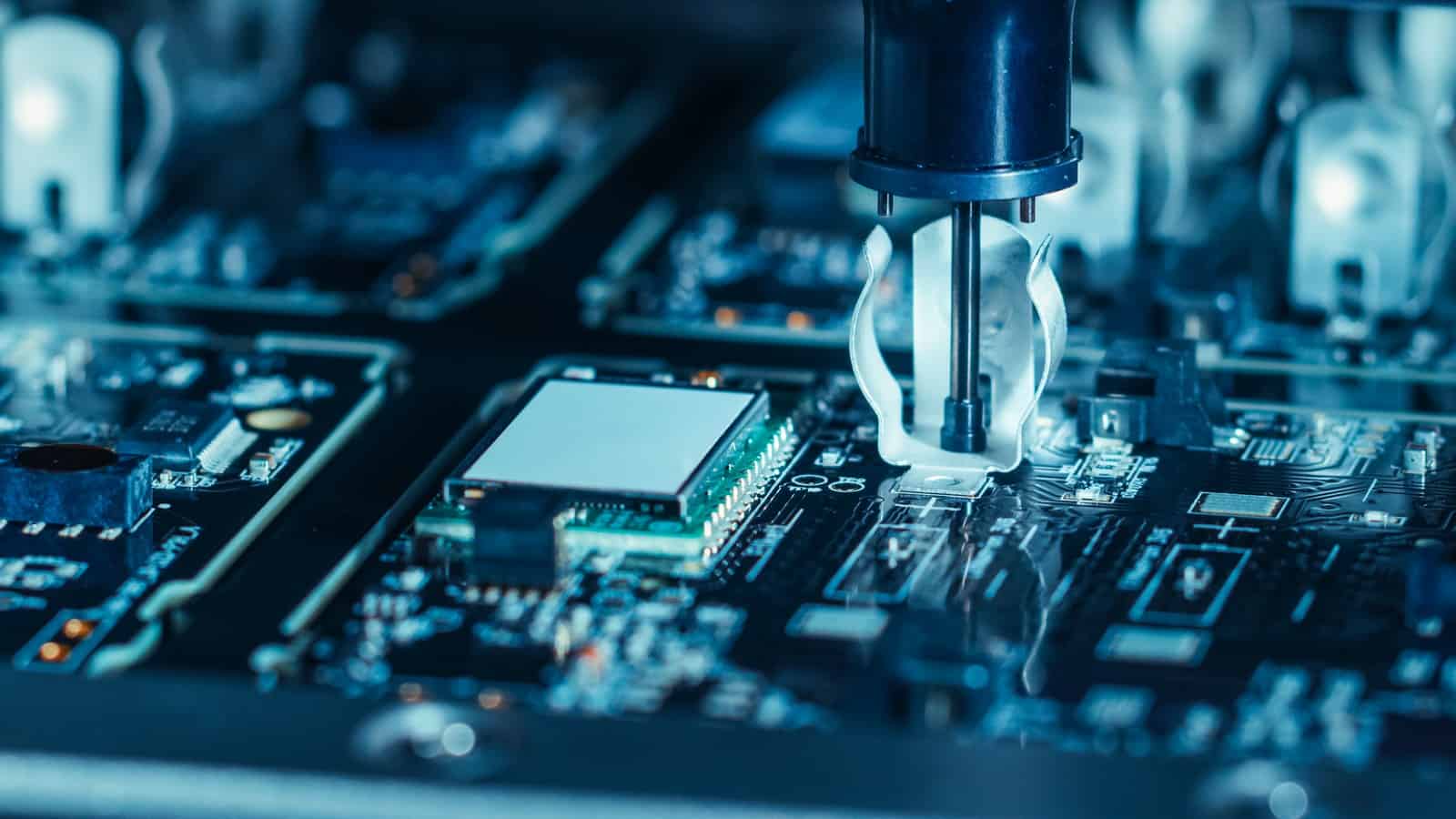

PCB ASSEMBLY UNCONTROLLED MOISTURE LEADS TO MICRO CORROSION

Printed Circuit Board which interconnect the conductors and circuit components on a electric board is widely used in almost all electronic devices. Ingress of moisture during PCB assembly can increase the number of failures during assembly, and decrease the circuit assemblies and its life. Effects of Uncontrolled Moisture Exposure to high moisture during Printed Circuit Board (PCB) assembly and manufacturing, leads to: Microscopic corrosion Adhesion failures Surface defects Decreased performance of the circuit board. Increase electrical resistance Decrease capacitance

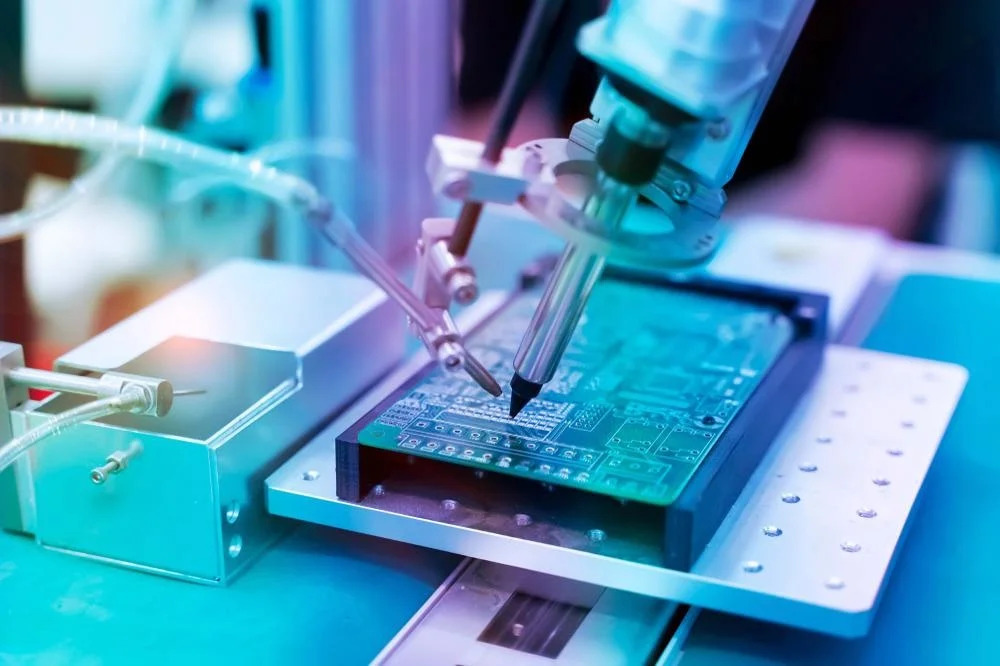

MOISTURE CONTROL SOLUTIONS FOR SEMICONDUCTOR ASSEMBLY OR MANUFACTURING

Semiconductors, microcircuits and microchips manufacturing requires very precise condition to be maintained in the manufacturing/ processing area. Components used in assembly or processing of semiconductors are generally hygroscopic and thus highly susceptible to high humidity conditions. Effects of Uncontrolled Humidity The hygroscopic components can leaf to: Corrosion of circuits points Operational failure of semiconductor assembly Improper adhesion of photo resists

MOISTURE CONTROL IN LITHIUM BATTERIES

Lithium battery production is undertaken in very critical and controlled (dry room) environment conditions. Non-maintenance of the desired RH during lithium cell manufacturing (<1%) and battery assembling (<10%) may lead to severe consequences. Lithium battery application is fast growing across diversified industries like Electronics, Automotive, Electric Vehicles (EV), Energy Storage, Solar, Telecom, Power, Defence, Space/Satellite, Healthcare etc. There is large scale production of lithium batteries and moisture acts as a major deterrent leading to the growth of this industry.